Hygienic conveyors keep dairy foods safe

“Manufacturing safe, wholesome products is perhaps the most important aspect of any dairy foods business, especially when it comes to consumer confidence,”

as John Lucey of the University of Wisconsin—Center for Dairy Research points out.*

SideDrive conveyors are designed with food safety in mind. Whether your dairy products are raw, pasteurized or cultured, SideDrive’s side-driven, plastic belting can help keep them safe.

Source: *Lucey, John. A collaborative effort to help small dairy manufacturers meet safety guidelines. Dairy Foods.

Your dairy product’s flexible conveyor solution is here

Hygienic zoning of dairy production lines is crucial to controlling cross-contamination and maintaining your product’s food safety. In fact, as the Innovation Center for U.S. Dairy points out, “History has shown that there is a greater likelihood of finding spoilage organisms or pathogens in uncontrolled or raw manufacturing areas than in production or ready-to-eat (RTE) areas. Managing the flow of personnel, supplies, air, and equipment significantly reduces the potential for cross-contamination.”*

Sanitary conveying equipment that’s completely configurable offers the ultimate flexible solution for the hygienic zoning of your dairy production line. Modular by design, SideDrive’s unique conveyor configurations allow you to optimize your production space based on your individual needs. Whether you need to retrofit an existing configuration or build one from scratch, SideDrive can design and configure a custom solution that you’ve only dreamt of, until now. The possibilities are endless!

Source: *Kedzierski, David, et al. Controlling Pathogens in Dairy Processing Environments: Guidance for the U.S. Dairy Industry. Innovation Center for U.S. Dairy, 2019.

Dairy conveyors for various applications

SideDrive sanitary conveyors are perfect for dairy products, whether they’re naked or in a primary or secondary package. Some examples include:

- Milk

- Condensed & dried milk

- Cream

- Sliced and shredded cheese

- Cream cheese

- Butter

- Yogurt, kefir, buttermilk, lassi and other cultured dairy products

- Ice cream, frozen yogurt and sherbet

- Pudding

- Whey

- Casein

Sanitary conveyors maintain your dairy product’s integrity

SideDrive conveyors help dairy processors ensure the integrity of their products while keeping them food-safe.

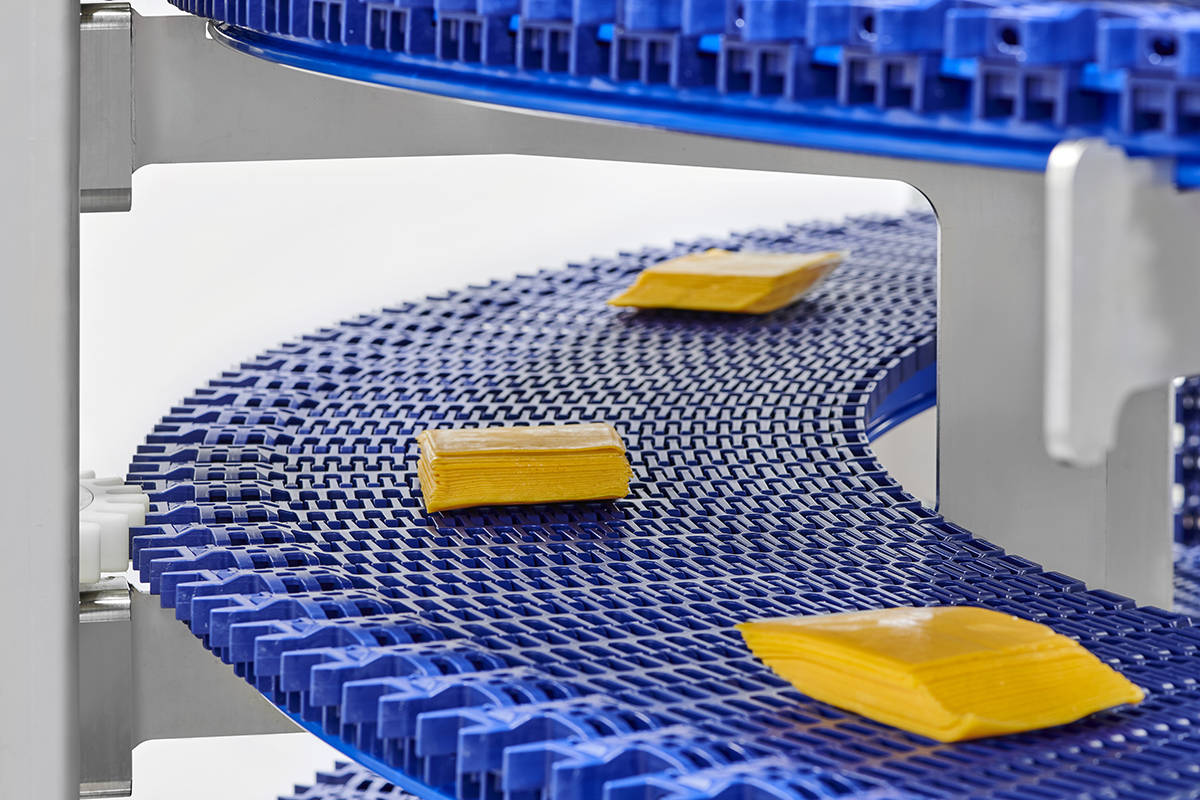

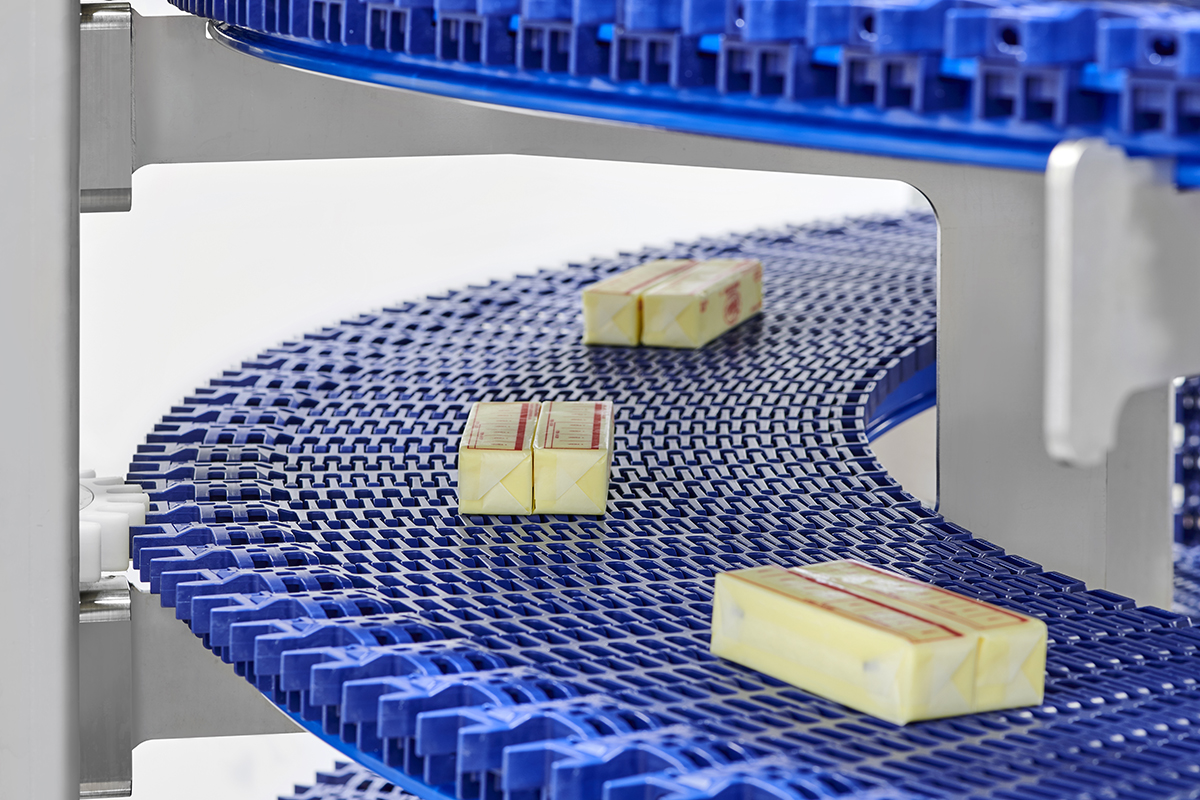

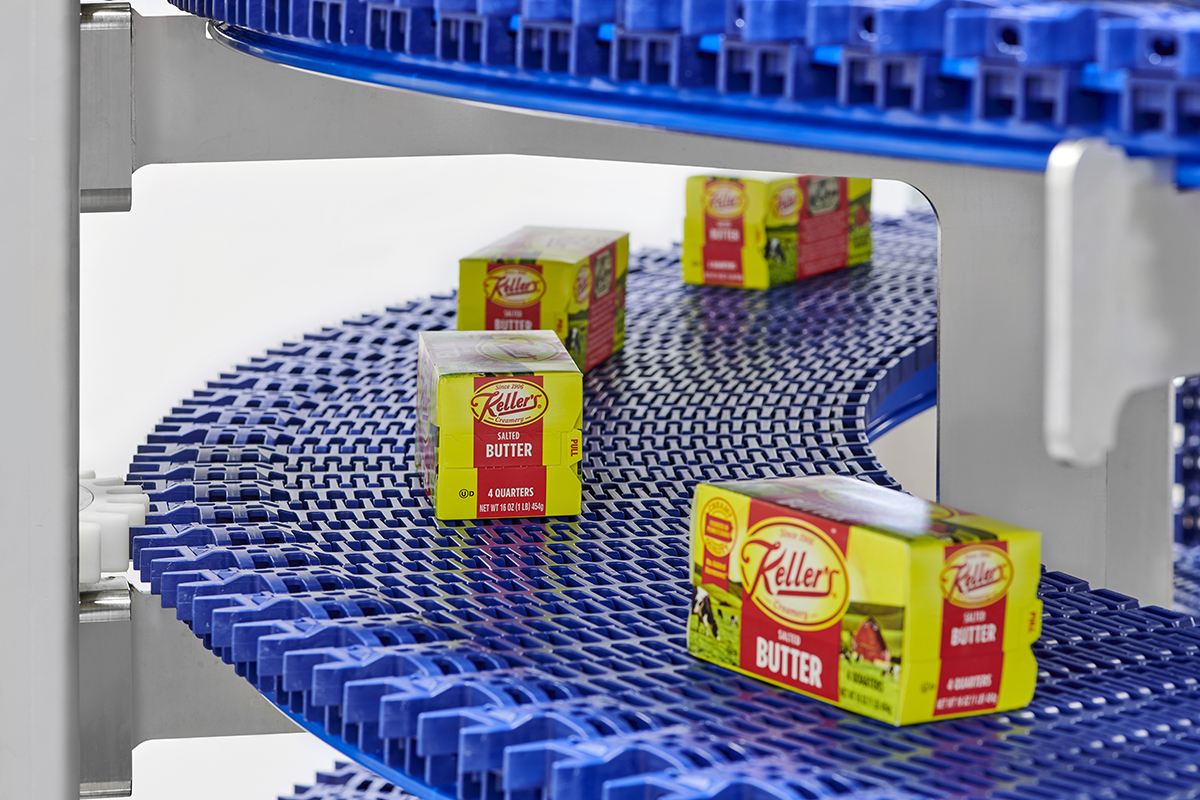

Conveyors made with food-safe materials protect your product from contamination. Transferless and spiral conveyors safely handle dairy products and prevent breakage. The gentle motion of the side-drive edge-driven conveyor belting keeps your products from moving around, preventing breakage and helping maintain integrity. Additionally, plastic belting prevents damage or marks caused by its rigid metal counterpart and helps reduce product loss due to adhesion.

Naked Products

Primary Packages

Secondary Packages

Keep your dairy production line clean & sanitary

According to the Innovation Center for U.S. Dairy, microbiological cleanability, being made of compatible materials, accessibility, self-draining surfaces, hollow areas hermetically sealed and no niche points are sanitary design principles that are “critical to ensure cleanability to eliminate harborage sites where microorganisms are protected from cleaning and sanitation.”*

SideDrive conveyors are hygienically designed to be compatible with food-safe dairy production lines. With an open, drumless design, unique food-safe edge-driven belt technology and a number of sanitary features, SideDrive spiral conveyors are the most hygienic on the market, and provide a conveyor solution for your food safety plan.

The small footprint of SideDrive spiral conveyors is beneficial for easy accessibility, cleaning and sanitation. Hygienic features and plastic belting make washdown more effective. These features include:

- Food-safe materials

- Sloped surfaces for easy run-off

- Cantilevered, stainless, open-frame design

- Plate frame structure easy for cleaning

- Hygienic feet

- Continuous welds to prevent harborage of bacteria

- Welded standoffs that separate parallel surfaces

- Solid UHMW wearstrips

Source: *Wilkin, Edith, et al. Control of Listeria Monocytogenes. Innovation Center for U.S. Dairy, 2017.