Sanitary conveyors gently keep frozen food products moving

Processing frozen food products requires vigilance to ensure food safety.

As the American Frozen Food Institute (AFFI) suggests, “Poor hygienic design, improper preventative maintenance and ineffective sanitation are the primary drivers leading to freezer-related contamination of finished food products.”* SideDrive conveyors can eliminate the common struggles associated with moving frozen foods on conveyors. Thanks to hygienic design and side-driven, plastic belting, you can help ensure the food safety of your product with SideDrive.

*AFFI. 2021. The Listeria Control Program Recommendations.

Frozen food conveyors with ultimate flexibility

Completely configurable and modular sanitary conveying equipment offers the ultimate flexible solution for your frozen food production line. Modular by design, SideDrive’s unique conveyor configurations allow you to optimize your frozen food production space based on your individual needs. Whether you need to retrofit an existing configuration or build one from scratch, SideDrive can design and configure a custom solution that you’ve only dreamt of, until now. The possibilities are endless!

Applications for versatile frozen food conveyors

Our sanitary frozen food conveyors are perfect for frozen products such as:

Frozen food conveyors that protect your products

Our sanitary side drive conveying systems keep your frozen foods safe and your production line moving.

Quality control and food safety are at the forefront of any frozen food operation. Frozen food conveyors made with food-safe materials protect your product from contamination. Transferless and spiral conveyors safely handle fragile frozen products and prevent breakage. The gentle motion of the side-drive edge-driven conveyor belting keeps your frozen food products from moving around, preventing breakage and helping maintain your product’s integrity. Additionally, plastic belting prevents damage or marks caused by its rigid metal counterpart and helps reduce product loss due to adhesion.

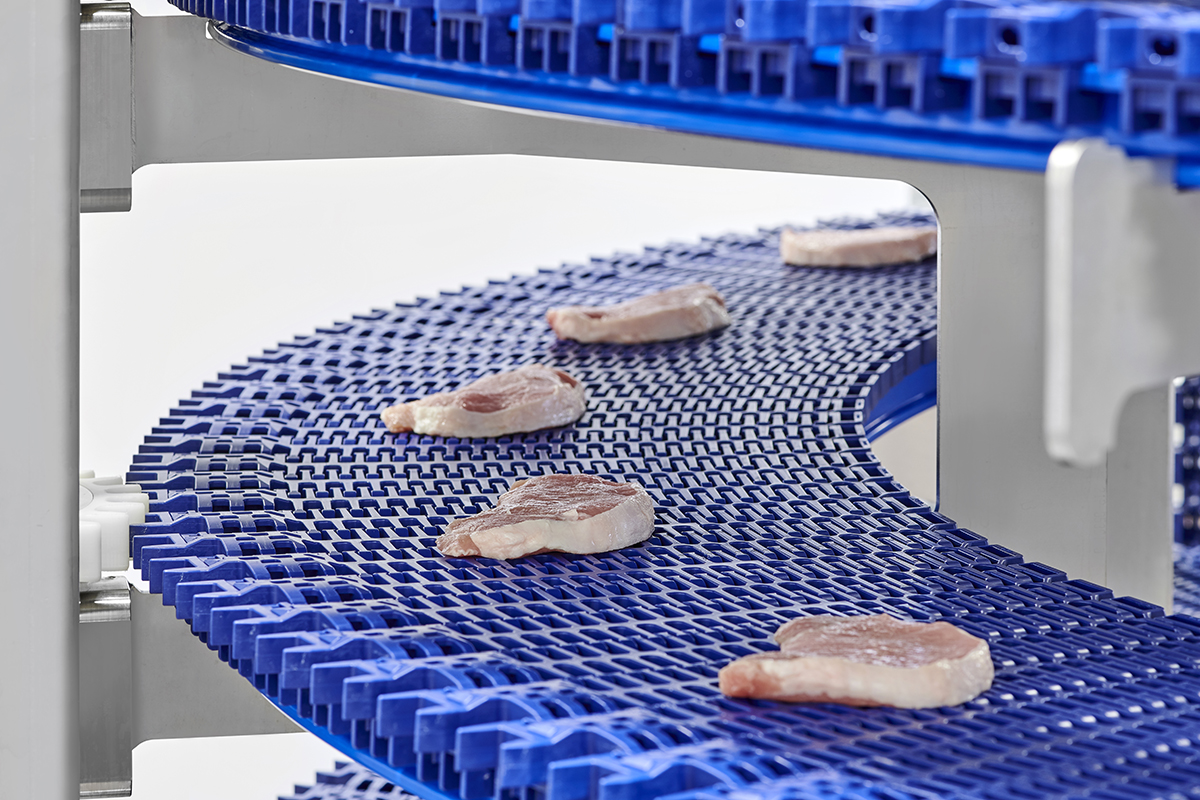

Naked Products

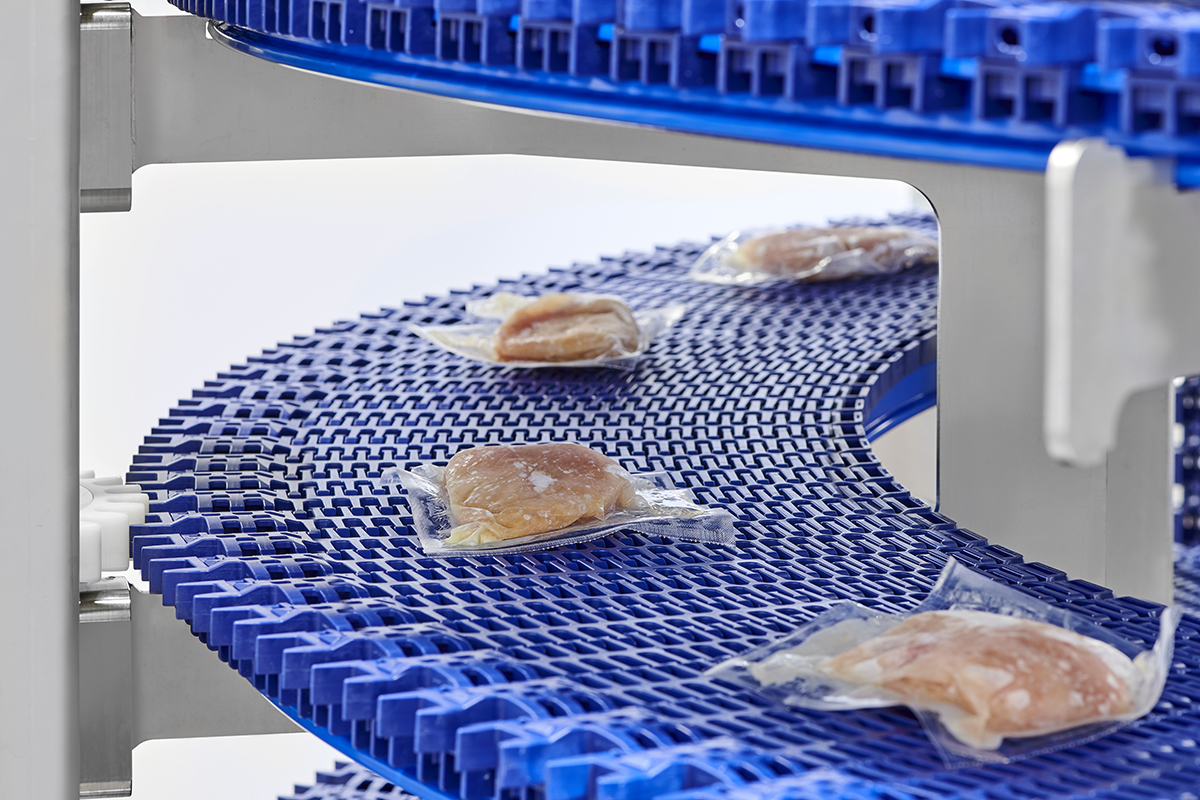

Primary Packages

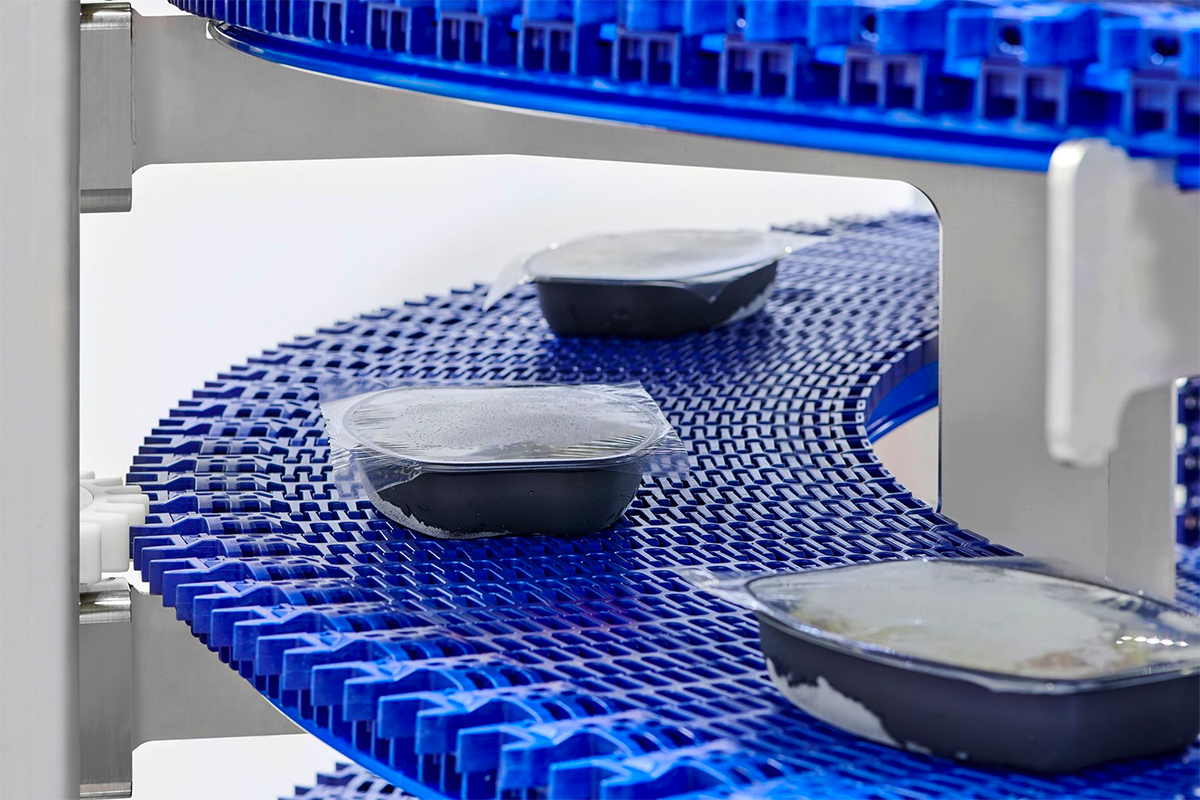

Secondary Packages

Sanitation made simple with SideDrive’s sanitary conveyors

Proper hygienic design and simplicity of washdown are crucial to the success of food processing and packaging solutions. In fact, according to the National Frozen & Refrigerated Foods Association (NFRFA), “Nearly two out of three consumers agree that better technology has a role in keeping food safe.”* SideDrive conveyors are hygienically designed with food safety as a top priority. With an open, drumless design, unique food-safe edge-driven belt technology and a number of sanitary features, SideDrive spiral conveyors are the most hygienic on the market.

*NFRA. How the frozen and refrigerated foods industry advances food safety for consumers. National Frozen & Refrigerated Foods Association.

Since cleanability is essential to frozen food conveyors, the small footprint of SideDrive spiral conveyors is beneficial for easy accessibility, cleaning and sanitation. Hygienic features and plastic belting make washdown more effective. These features include:

- Food-safe materials

- Sloped surfaces for easy run-off

- Cantilevered, stainless, open-frame design

- Plate frame structure easy for cleaning

- Hygienic feet

- Continuous welds to prevent harborage of bacteria

- Welded standoffs that separate parallel surfaces

- Solid UHMW wearstrips

In line with the Listeria Control Program recommendations laid out by the AFFI, SideDrive conveyors are complementary to food safety programs that include considerations such as hygienic zoning, Good Manufacturing Practices (GMPs) and freezer management.